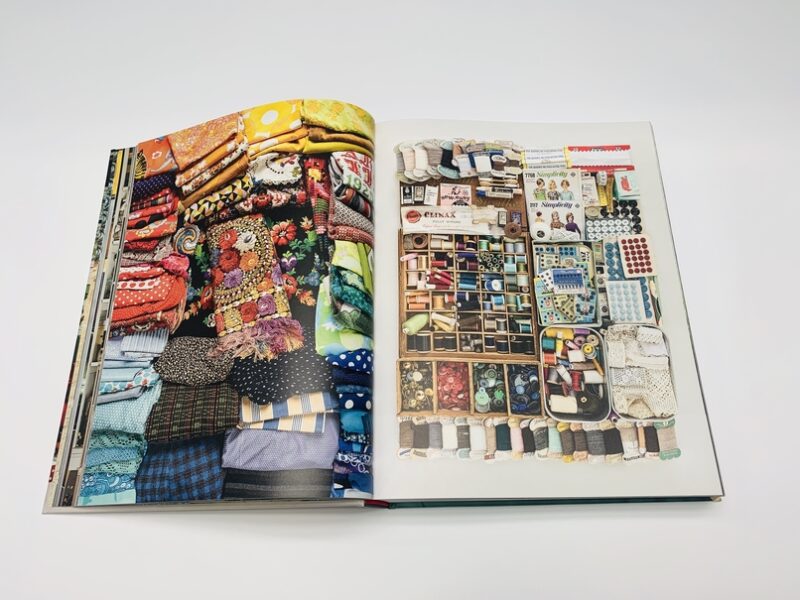

Komori Lithrone HUV printing technology is perfect for demanding projects. Normally oil based inks need extra time to dry and using uncoated paper in printing may end up in unexpected results. Imagery on uncoated paper may look good at the moment of printing, but once the inks absorb into the sheet, the final result can become flat and dull. There´s a chance to avoid it all when using HUV printing.

The ink dries instantly when using UV light. That ensures mark free print. Since the ink dries on the surface, the color you see in the printing is the colour you see in the final product. There is no need for spray powder. The HUV printed images are bright and vibrant. The HUV inks give sharp and live colours not only on matt and gloss paper, but also on uncoated paper too.

Eco-friendly choice

HUV printing is eco-friendly because of the reduced energy required for the production process. There are no omissions to ozone nor odours, which makes the environment more healthy for the staff. A single HUV lamp can cure up to 400% ink coverage plus coating at maximum press speed. If you care about the environment, then your choice is HUV printing.